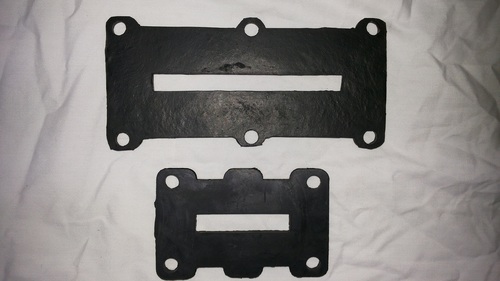

Silicon Washer

Silicon Washer Specification

- Gasket Coefficient

- 1.5 - 2.5

- Vaccum Range

- Suitable for high vacuum applications

- Working Temperature

- -60C to +200C

- Standard

- ASTM, DIN, or as per customer requirement

- Pressure Resistance

- Good (varies by size/thickness)

- Temperature Resistance

- Up to 250C

- Medium

- Resistant to most chemicals, water, oil, and solvents

- Thickness

- 0.5 mm to 5 mm

- Type

- Flat Washer

- Hardness

- 60-70 Shore A

- Material

- Silicon

- Shape

- Washer

- Outer Ring

- Customizable

- Inner Ring

- Customizable

- Application

- Sealing, Insulation, Spacing in electrical and industrial assemblies

- Technology

- Molded

- Reusable

- Yes

- Compression Set

- Low

- Elongation At Break

- 300% - 500%

- Tolerance

- As per ISO 2768

- Tear Resistance

- Good

- Odor

- Odorless

- Custom Sizes

- Available on request

- Surface Finish

- Smooth

- Dielectric Strength

- High (Suitable for electrical insulation)

- Non-Toxic

- Yes, food grade on request

- Color

- Red, translucent, or as per requirement

- Environmental Resistance

- UV and ozone resistant

Silicon Washer Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Main Domestic Market

- South India, Karnataka

About Silicon Washer

Robust Electrical Insulation and Sealing

Our silicon washers are specifically developed for sealing, insulation, and spacing in a variety of electrical and industrial assemblies. Their superior dielectric strength ensures effective insulation, while their robust material resists high temperatures, chemicals, and environmental stressors, protecting sensitive components and preventing leaks or corrosion.

Customizable for Precise Applications

Tailored to your specifications, these washers are available in red, translucent, or custom colors. Both the inner and outer rings, as well as thickness (0.5 mm to 5 mm), can be customized according to your requirements. Every washer meets ISO 2768 tolerances or other international standards such as ASTM and DIN, ensuring reliable quality and fitting.

Safe, Durable, and Environmentally Resistant

Constructed with food-grade and non-toxic silicon upon request, these odorless washers are safe for sensitive environments. They resist degradation under UV, ozone, and harsh chemicals, making them highly durable. Reusable and easy to install, they provide long service life and cost savings across repeated usage.

FAQs of Silicon Washer:

Q: How do silicon washers benefit electrical and industrial assemblies?

A: Silicon washers act as highly reliable insulators and seals, preventing electrical leakage, reducing vibration, and protecting against chemical exposure and weather effects. Their high dielectric strength and low compression set make them indispensable for secure, maintenance-free operation in demanding assemblies.Q: What customization options are available for silicon washers?

A: You can request custom colors, sizes, thicknesses (from 0.5 mm to 5 mm), and specific inner or outer ring dimensions. Food grade and non-toxic versions are offered for special applications, and washers can be manufactured as per ASTM, DIN, or customer-specific standards.Q: When should I use a silicon washer instead of other washer materials?

A: Silicon washers are ideal for situations requiring electrical insulation, resistance to extreme temperatures (from -60C to +250C), exposure to UV or ozone, frequent contact with chemicals, and applications where non-toxic or food-safe materials are necessary.Q: Where are these silicon washers commonly utilized?

A: They are widely used in electrical, electronic, and industrial assemblies, particularly for sealing, insulation, and spacing. Their chemical, water, oil, and solvent resistance also make them suitable in laboratories, food processing, and machinery exposed to harsh environments.Q: What is the process for ordering custom silicon washers?

A: Simply specify your required dimensions, color, material grade, and any compliance standards needed. As a manufacturer, exporter, and supplier, we collaborate with customers to design and produce washers that precisely match their technical and regulatory requirements.Q: How does the low compression set and good tear resistance contribute to washer performance?

A: A low compression set means the washer retains its original shape even under prolonged loads, providing consistent sealing and insulation. Good tear resistance ensures that washers withstand assembly and operational stresses without breaking, enhancing reliability and reducing maintenance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Gaskets Category

Speedometer Gaskets

Minimum Order Quantity : 1000 Pairs

Standard : OEM standard

Shape : Other, Circular

Material : Other, Rubber composite

Vaccum Range : Up to 0.001 mbar

Working Temperature : 30C to +120C

Transformers Seals and Gaskets

Minimum Order Quantity : 500 Pairs

Standard : IEC 60076, IS 4253

Shape : Other, Rectangular, Circular, Custom

Material : Other, Nitrile Rubber, Cork, EPDM, Neoprene, Silicone

Vaccum Range : Up to 1x10 mbar

Working Temperature : 40C to +120C

Silicon Oven Gaskets

Minimum Order Quantity : 500 Meters

Standard : FDA Grade, Food Safe, IS Standard

Shape : Other, Ring / Gasket

Material : Silicon

Vaccum Range : 0.01 mbar

Working Temperature : 60C to +250C (up to +300C shortterm)

Quality Rubber washers

Minimum Order Quantity : 1000 Pieces

Standard : IS 5382 / ASTM D2000

Shape : Other, Round

Material : Other, HighGrade Rubber

Vaccum Range : 0.01 mbar to 1 bar

Working Temperature : 40C to +120C

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free