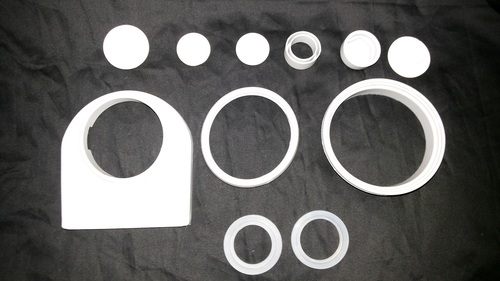

Rubber moulded components

Rubber moulded components Specification

- Flame Resistance Level

- Flame retardant grades available

- Size

- Custom sizes available

- Style

- Customized as per requirement

- Product Type

- Rubber Moulded Components

- Width

- Custom as per drawing/specification (typically 2 mm to 500 mm)

- Volatile Matter (%)

- <1%

- Water Absorption

- Very low to negligible

- Density

- 1.1 Gram per cubic centimeter(g/cm3)

- Resistance level

- Good chemical, oil, abrasion and aging resistance

- Color

- Black, or as per customer specification

- Thermal Conductivity

- Low (Typical for solid rubber)

- Usage & Applications

- Automotive, electrical, engineering, machinery, sealing and gasketing, vibration dampening, fluid transfer, weatherproofing, electronic enclosures

- Material

- Natural rubber, EPDM, Nitrile, SBR, Silicone, Neoprene, or as specified

- Diameter

- Upto 600 mm depending on design

- Weight

- Varies as per component dimension and material

- Hardness

- 30 to 90 Shore A

- Rubber Type

- Natural Rubber, EPDM, Nitrile, Silicone, SBR, Neoprene

- Temperature Resistance

- -40C to +220C (depends on rubber type)

- Compression Ratio

- Typically 5% - 20% depending on application

- Tolerance

- 0.05 mm or as per customer requirement

- Components

- Seals, gaskets, bushings, bellows, washers, couplings, boots, O-rings, buffers

- Feature

- Precision engineered, high elasticity, durable, ozone and weather resistant

- Part Type

- Moulded mechanical part

- Length

- Custom as per design specification

- Ash %

- Max 2%

- Surface Finish

- Smooth, custom textured, or grained as needed

- Thickness

- 1 mm to 30 mm (customizable)

- Tensile Strength

- 8 to 20 MPa depending on grade

- Nitrogen Content (%)

- Negligible

- Natural Rubber

- Available as an option

- Electrical Insulation

- Good (for most grades except conductive rubber)

- Adhesion Capabilities

- Bonding with metal, plastic or fabric possible

- Shape

- Custom as per design (round, square, complex geometry)

- Customization

- Dimensions, material, color, hardness, and finish as per client need

- Aging Resistance

- Excellent resistance to ozone, UV, and aging for selected compounds

- MOQ

- As per client requirement

- Certificates

- RoHS, REACH, ISI, ISO compliance possible

- Manufacturing Process

- Compression moulding, injection moulding, transfer moulding

- Packaging

- Poly bag, carton, pallet, as specified by customer

- Elongation at Break

- 200% to 600% (depending on material)

Rubber moulded components Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Main Domestic Market

- Karnataka, South India

About Rubber moulded components

Rubber Moulded Components: Usage & Applications

Our custom rubber moulded components are ideal for applications across automotive, electrical, engineering, and machinery sectors. Use them for sealing and gasketing, vibration damping, fluid transfer, weatherproofing, and electronic enclosure protection. Direction of use is simplefit the moulded part as per your design specifications, ensuring optimal performance and durability. Components like bushings, seals, bellows, and more offer splendiferous adaptability for every operational requirement.

Supply, Certifications & Dispatch Information

Delivery times for rubber moulded components are flexible, determined by the quantity and customization. Supply is prompt with options for poly bag, carton, or pallet packing, ensuring secure dispatch. All products can be quoted FOB major Indian ports. Certifications including RoHS, REACH, ISI, and ISO support your compliance needs. For packing and dispatch details, request a quotation, and expect praiseworthy service from our exporter, manufacturer, and supplier teams.

FAQs of Rubber moulded components:

Q: How can I specify custom shapes and sizes for rubber moulded components?

A: You can provide drawings or design specifications for round, square, or complex geometries, and select custom dimensions, thickness, width, and finish as per your requirements.Q: What is the manufacturing process used for these components?

A: We utilize top moulding processes like compression, injection, and transfer moulding to ensure each component is precision engineered for your application.Q: When can I expect delivery after placing an order?

A: Delivery depends on order quantity and customization; dispatch timelines are provided in the quotation, with supply and packing tailored to your needs.Q: Where are these rubber moulded components exported from?

A: These products are manufactured and supplied from India, with FOB shipment available through major Indian ports to your destination.Q: What certifications support the quality and compliance of these components?

A: Rubber moulded components can be supplied with RoHS, REACH, ISI, and ISO certifications to ensure compliance with global standards.Q: What are the primary usage benefits of these rubber moulded parts?

A: They provide excellent chemical, oil, abrasion, and weather resistance, high elasticity, and durable performance for sealing, damping, and protection in demanding environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Components Category

Rubber Handles

Minimum Order Quantity : 1000 Pieces

Feature : Comfort grip, sweat resistant, durable

Components : Rubber sleeve, optional inner core

Part Type : Handle grip

Ash % : 1%

Length : 125 mm (standard); customizable

Rubber Foot Rest Cover

Minimum Order Quantity : 1000 Pieces

Feature : Antislip, weather resistant

Components : Single Foot Rest Rubber Cover

Part Type : Replacement Cover for Foot Rest

Ash % : 6%

Length : 1015 cm

Rubber bonded metals

Minimum Order Quantity : 500 Pieces

Feature : High durability, shock absorption, antivibration, corrosion resistant

Components : Steel and vulcanized rubber layer

Part Type : Bonded metal component

Ash % : <4%

Length : Cuttolength per specification

Silicon Transparent tube

Minimum Order Quantity : 500 Meters

Feature : Nontoxic, Odorless, Clear visibility, Good flexibility

Components : Single extruded silicon tube

Part Type : Tubing

Ash % : Less than 1%

Length : Custom cut lengths, standard roll length: 150 meters

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS