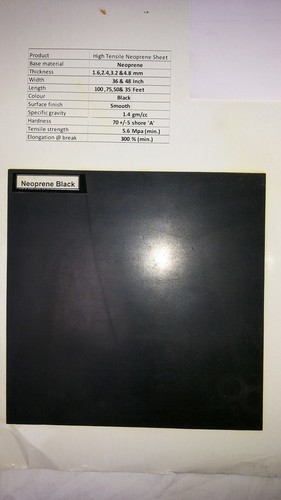

Neoprene Black sheets

Neoprene Black sheets Specification

- Tolerance

- 0.2 mm

- Length

- Up to 10 meters or as per requirement

- Components

- Single material (neoprene)

- Natural Rubber

- No (synthetic rubber)

- Product Type

- Neoprene Black Sheet

- Volatile Matter (%)

- Less than 2%

- Thickness

- 1 mm to 25 mm

- Size

- Customizable sizes available

- Resistance level

- High resistance to chemicals & weather

- Flame Resistance Level

- Moderate, self-extinguishing

- Tensile Strength

- 5 - 12 MPa

- Width

- 1000 mm to 1500 mm

- Hardness

- 605 Shore A

- Thermal Conductivity

- 0.15 W/mK

- Compression Ratio

- 30-40%

- Temperature Resistance

- -30C to +100C

- Weight

- Varies with size and thickness

- Rubber Type

- Neoprene

- Density

- 1.6 Gram per cubic centimeter(g/cm3)

- Usage & Applications

- Industrial gaskets, weather stripping, insulation, automotive parts, padding, seals, vibration dampening, marine uses

- Water Absorption

- Low

- Part Type

- Sheet

- Ash %

- Max 5%

- Nitrogen Content (%)

- 0.3 - 0.5%

- Style

- Smooth or textured finish

- Feature

- Oil, chemical, weather and ozone resistance; durable; flexible; waterproof

- Diameter

- N/A (Sheet form)

- Color

- Black

- Material

- Neoprene (Chloroprene rubber)

- Surface Finish

- Matte or glossy

- Specific Gravity

- 1.401.60

- Working Pressure

- Up to 10 bar

- Elongation at Break

- 200350%

- Tear Resistance

- Moderate to High

- Electrical Resistance

- High (not recommended for dielectric applications)

- Minimum Order Quantity

- 1 sheet or as specified by supplier

- Standards Met

- ASTM D2000 or equivalent

- Storage Life

- Up to 5 years under ideal storage

Neoprene Black sheets Trade Information

- Minimum Order Quantity

- 500 Pieces

- Main Domestic Market

- South India, Karnataka

About Neoprene Black sheets

Versatile Application Surfaces for Neoprene Black Sheets

Neoprene Black Sheets are designed for compatibility with various surfaces, including metal, glass, wood, and concrete. These sheets deliver exceptional performance in diverse industrial environments, making them ideal for weather stripping, insulation, marine components, automotive parts, and gasket fabrication. Their superior oil, chemical, and ozone resistance ensures lasting function in demanding facilities. The smooth or textured finish options allow seamless integration into application areas involving vibration dampening, padding, and high-pressure sealing, providing reliable solutions for a range of usage needs.

Certified Quality and Reliable Global Supply of Neoprene Black Sheets

Neoprene Black Sheets conform to ASTM D2000 or equivalent standards for consistent, reliable quality. Delivered across all major export markets, our supply capability supports large orders as well as custom batch requirements. With arrival guaranteed through a seamless distribution process, each shipment reflects our commitment to timely delivery and customer satisfaction. As a leading exporter, manufacturer, and supplier from India, we ensure a steady supply to meet dynamic global demands efficiently and reliably.

FAQs of Neoprene Black sheets:

Q: What are the main industrial uses of Neoprene Black Sheets?

A: Neoprene Black Sheets are primarily used for making gaskets, weather stripping, insulation, automotive parts, padding, seals, and vibration dampening components. They are also applied in marine and industrial environments due to their durability and resistance to oil, chemicals, and weather.Q: How can the size and surface finish of Neoprene Black Sheets be customised?

A: You can personalise Neoprene Black Sheets by specifying your required width (from 1000 mm to 1500 mm), thickness (from 1 mm to 25 mm), and length (up to 10 meters or as needed). Both matte and glossy, as well as smooth or textured finishes, are available to suit various applications.Q: What certifications assure the quality of these Neoprene Black Sheets?

A: These sheets meet the ASTM D2000 or equivalent international standards, ensuring high quality, performance consistency, and suitability for demanding industrial applications globally.Q: Where can Neoprene Black Sheets be supplied and what is the minimum order quantity?

A: We supply Neoprene Black Sheets globally, especially to major export markets. The minimum order quantity is one sheet or as specified by the supplier, making it accessible for both small and bulk orders.Q: What is the storage life and ideal storage process for Neoprene Black Sheets?

A: When stored under ideal conditionscool, dry, and away from direct sunlightNeoprene Black Sheets have a storage life of up to 5 years, preserving their mechanical and chemical properties.Q: What key benefits do Neoprene Black Sheets offer for industrial applications?

A: Neoprene Black Sheets provide high resistance to oil, chemicals, weather, and ozone. They are waterproof, durable, moderately flame-resistant, and can withstand a wide temperature range, making them particularly useful in harsh or variable industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Sheets Category

Thick Rubber Sheets

Minimum Order Quantity : 500 Pieces

Natural Rubber : Yes (Available in NR, SBR, Neoprene, EPDM)

Product Type : Thick Rubber Sheet

Volatile Matter (%) : <1.5%

Thickness : 3 mm to 25 mm

Tolerance : 0.5 mm

Rubberised Sheets

Minimum Order Quantity : 500 Pieces

Natural Rubber : Present; blended as per application

Product Type : Rubberised Sheet

Volatile Matter (%) : 0.5%

Thickness : Range from 2 mm up to 25 mm

Tolerance : 0.1 mm

Silicon Sponge Sheets

Minimum Order Quantity : 500 Pieces

Natural Rubber : No; made from synthetic silicon rubber

Product Type : Silicon Sponge Sheet

Volatile Matter (%) : <3%

Thickness : 1 mm to 25 mm (customizable)

Tolerance : 0.5 mm

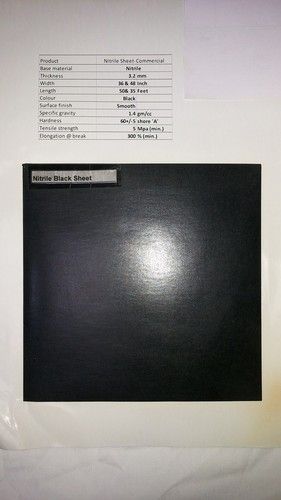

Nitrile Rubber Sheets

Minimum Order Quantity : 500 Pieces

Natural Rubber : No

Product Type : Rubber Sheet

Volatile Matter (%) : Less than 2%

Thickness : 1 mm to 50 mm

Tolerance : 0.2 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS