Sponge Sheets

Sponge Sheets Specification

- Size

- Custom sizes available

- Feature

- Soft, lightweight, flexible, compressible, closed cell structure

- Thermal Conductivity

- Low, provides insulation

- Hardness

- Shore A 15-40

- Compression Ratio

- 30% to 40%

- Surface Finish

- Smooth

- Components

- Rubber sponge compound

- Water Absorption

- Low, closed cell structure minimizes absorption

- Length

- Up to 2000 mm

- Tolerance

- 0.2 mm

- Color

- Black, Grey, White, Red, Blue

- Style

- Plain/Sheet

- Natural Rubber

- Available as Natural, EPDM, Silicone, Neoprene, and other variants

- Temperature Resistance

- -40C to +100C (varies by material)

- Part Type

- Sheet

- Tensile Strength

- 3.5 - 8 MPa

- Width

- Up to 1000 mm

- Ash %

- < 4%

- Material

- Rubber (depends on type: Natural, EPDM, Neoprene, Silicone)

- Thickness

- 1 mm to 50 mm

- Rubber Type

- EPDM, Natural, Neoprene, Silicone, Nitrile

- Resistance level

- Good resistance to water, chemicals, and weathering

- Usage & Applications

- Gasketing, cushioning, packing, insulation, sealing, and sound-proofing.

- Weight

- Varies per size and grade

- Density

- 350 Gram per cubic centimeter(g/cm3)

- Flame Resistance Level

- Flame retardant grades available

- Product Type

- Sponge Sheet

- Odor

- Mild characteristic

- RoHS Compliance

- Yes, compliant with major environmental and safety regulations

- Packaging Type

- Rolls, sheets, cartons or as per customer requirement

- Adhesive Backing

- Available upon request

- UV Resistance

- Available in UV resistant grades

- Electrical Insulation

- Provides good electrical insulation

- Recovery Rate

- Excellent dimensional recovery after compression

- Elongation at Break

- Up to 150%

- Ozone Resistance

- Excellent in EPDM variant

- Storage Instructions

- Store in a cool, dry place, away from direct sunlight and heat sources

Sponge Sheets Trade Information

- Minimum Order Quantity

- 500 Pieces

- Main Domestic Market

- South India, Karnataka

About Sponge Sheets

Versatile Applications

Sponge Sheets are versatile materials ideal for gasketing, cushioning, packing, insulation, sealing, and sound-proofing. They are engineered to perform reliably across numerous industries, offering customizable solutions that meet specific dimensional and functional requirements. Thanks to their closed cell structure, these sheets excel in environments requiring water, chemical, and weather resistance, making them a go-to choice for both indoor and outdoor installations.

Outstanding Physical and Chemical Resistance

Sponge Sheets offer robust protection against ozone, UV radiation, water, and many chemicals, particularly in EPDM and other specialty variants. Their excellent dimensional recovery and compressibility make them especially suitable for applications where lasting performance is critical. These properties ensure that the material maintains its form and function even under pressure, contributing to long service life.

FAQs of Sponge Sheets:

Q: How can I select the right Sponge Sheet material for my application?

A: Selecting the correct Sponge Sheet material involves considering your applications requirements, such as exposure to chemicals, temperature range, and need for flame or UV resistance. EPDM is great for ozone and outdoor use, while Neoprene offers chemical resistance, and Silicone provides wide temperature tolerance. Our experts can guide you based on your specific needs.Q: What are the main benefits of using Sponge Sheets in industrial or commercial settings?

A: Sponge Sheets offer excellent compressibility, dimensional recovery, electrical insulation, and resistance to water, chemicals, and weathering. Their lightweight, flexible, and soft nature means they can cushion and seal efficiently, making them suitable for gasketing, sound-proofing, and insulation in diverse environments.Q: When should I opt for adhesive backing on my Sponge Sheets?

A: Adhesive backing is advisable when ease of installation is important or where sheets need to be fixed onto surfaces without mechanical fasteners. We can provide sheets with adhesive backing on request to streamline your application process and enhance convenience.Q: Where should Sponge Sheets be stored before use?

A: To maintain their properties, Sponge Sheets should be stored in a cool, dry place, away from direct sunlight and heat sources. Following these storage guidelines will help preserve the products flexibility, resilience, and other performance features.Q: What is the typical process for ordering and customization?

A: You can order Sponge Sheets in rolls, sheets, or cartons, with sizes and thicknesses customized according to your requirements. Simply specify dimensions, material type, color, and any special features like UV resistance or adhesive backing, and well manufacture and supply to your exact specifications.Q: How are these Sponge Sheets beneficial for electrical insulation?

A: Sponge Sheets are designed with low thermal conductivity and high electrical resistivity, making them an excellent choice for insulating applications where electrical safety is a priority. The closed cell structure further minimizes moisture penetration, enhancing electrical performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Sheets Category

Rubberised Sheets

Minimum Order Quantity : 500 Pieces

Hardness : 60 to 80 Shore A

Thickness : Range from 2 mm up to 25 mm

Style : Plain, Textured, or Patterned as per requirement

Length : Up to 10 meters/roll

Product Type : Rubberised Sheet

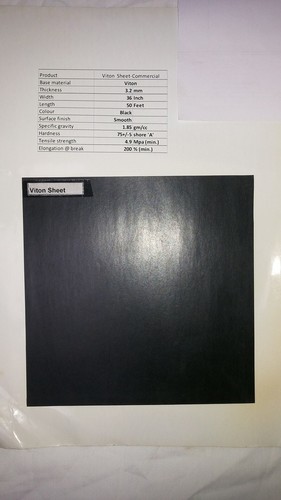

Vitron Rubber Sheets

Minimum Order Quantity : 500 Pieces

Hardness : 655 Shore A

Thickness : 0.5 mm to 50 mm

Style : Flat Sheet

Length : Up to 10 meters or as required

Product Type : Rubber Sheet

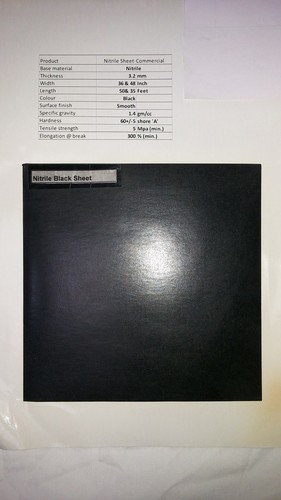

Nitrile Sheets

Minimum Order Quantity : 500 Pieces

Hardness : 65 5 Shore A

Thickness : 1 mm to 25 mm

Style : Flat Sheet

Length : Up to 10 meters

Product Type : Nitrile Rubber Sheet

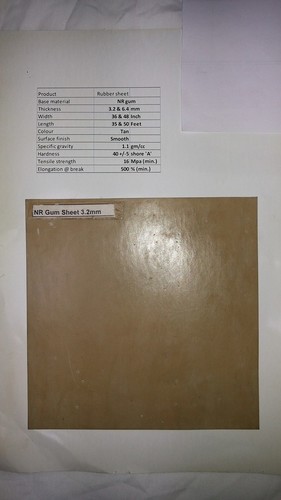

High Resistance To Cut, Tear And Abrasion NR Gum Sheets

Minimum Order Quantity : 500 Pieces

Hardness : 3845 Shore A

Thickness : 1 mm to 50 mm

Style : Plain/Sheet

Length : Up to 10 meters or as required

Product Type : NR Gum Sheet

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free