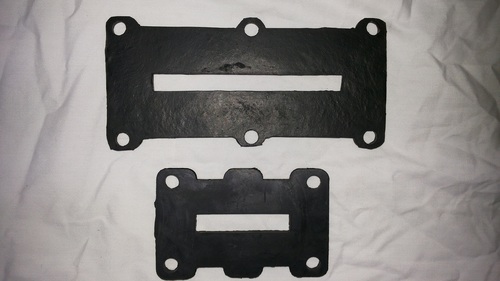

Customized rubber gaskets

Customized rubber gaskets Specification

- Thickness

- 0.5mm to 50mm (customizable)

- Standard

- ASTM, IS, DIN, JIS or as per customer standards

- Working Temperature

- -40C to +220C (Depending on Material)

- Gasket Coefficient

- 0.75 to 1.2 (varies with material and finish)

- Type

- Flat Gasket, Ring Gasket, Custom Profile Gasket

- Pressure Resistance

- Up to 150 bar

- Temperature Resistance

- Up to 220C

- Vaccum Range

- Up to 750 mm Hg

- Medium

- Water, Oil, Air, Acids, Alkalis, Chemicals

- Hardness

- 30-90 Shore A (as per requirement)

- Material

- EPDM, Nitrile, Silicone, Neoprene, Natural rubber or as per customization

- Shape

- Round, Rectangular, Square, Oval, or customized shapes

- Outer Ring

- Optional, available as per design

- Inner Ring

- Optional, available as per design

- Application

- Sealing, Fluid Control, Flange Connections, Automotive, Chemical Industry, HVAC, Pipe Fittings

- Technology

- Compression Molding, Injection Molding, Die Cutting

- Customization

- Dimensions, Material, Hardness, Profile, Color

- Water Absorption

- Minimal/Negligible

- Ozone Resistance

- Yes (on request)

- Compression Set

- 10-35% (as per ASTM D395)

- Tensile Strength

- 7-20 MPa (according to chosen material)

- Elongation at Break

- 150-400%

- Color

- Black, White, Red, Blue, Transparent or custom colors

- Flame Retardancy

- Optional, available as per requirement

- UV Resistance

- Available (material dependent)

- Finish

- Smooth, Textured, or as per design specification

Customized rubber gaskets Trade Information

- Main Domestic Market

- South India, Karnataka

About Customized rubber gaskets

Customised rubber gaskets are crucial components or devices that are profusely employed in plumbing, HVAC systems, automobile engineering, and similar industrial usage or applications. High quality rubber materials, with exceptional durability, flexibility has been put into use for manufacturing them. Our gaskets are chemically resistant, and able to withstand harsh environments, making them a valuable asset in any industry. These provided Customised rubber gaskets are manufactured to suit the standard certain applications. Our skilled engineers and workers collaborate closely with clients to create custom solutions for gratifying them. Users are ensured that the gaskets are a perfect match for their application.

Versatile Customization for Diverse Requirements

We offer tailored rubber gaskets in various shapesincluding round, rectangular, oval, and custom profilesand a wide hardness spectrum. Select from finishes like smooth or textured and add optional features, such as inner or outer rings, to suit specific design requirements. Each gasket can be customized for thickness, material, size, and functional resistance, bringing precision to industrial sealing and fluid control applications.

Material Excellence and Technology

Our gaskets use premium materials like EPDM, Nitrile, Silicone, Neoprene, and Natural rubber, each with distinct advantages in chemical resistance, temperature tolerance, and mechanical properties. Manufacturing technologies, including compression and injection molding or die cutting, ensure consistent quality and performance, complying with leading international standards. Optional features like flame retardancy, UV, and ozone resistance further expand usage possibilities.

FAQs of Customized rubber gaskets:

Q: How can customized rubber gaskets be tailored to my specific application requirements?

A: You can specify the dimensions, profile, material, hardness, color, finish, and optional features, such as inner or outer rings. Our design team works with you to match these requirements to your intended use, whether its automotive, chemical, HVAC, or other industrial contexts.Q: What materials are available for these gaskets, and how do I choose the right one?

A: Available materials include EPDM, Nitrile, Silicone, Neoprene, Natural rubber, or custom blends. Selection depends on the required resistance to temperature, chemicals, pressure, or environmental conditions. We can recommend the most suitable material based on your applications specific demands.Q: Where are these rubber gaskets manufactured and supplied?

A: We manufacture and export these rubber gaskets from India, supplying to a diverse range of industries nationally and internationally. Our facilities follow ASTM, IS, DIN, and JIS standards for global compatibility.Q: What is the process for ordering customized gaskets from your company?

A: Contact our sales team with your requirements, including shape, dimensions, material, and any special features. Well provide guidance, design assistance, and a quotation. Once specifications are finalized, production begins using your chosen technology and finishes.Q: When is UV and ozone resistance required for rubber gaskets?

A: UV and ozone resistance is important for gaskets exposed to outdoor elements, electrical environments, or long-term durability in harsh conditions. These features are available as per request and material compatibility.Q: How do these gaskets benefit fluid control and sealing applications?

A: Our gaskets provide reliable sealing for fluids such as water, oil, acids, alkalis, and chemicals, with minimal water absorption and customizable compression set. Their tailored properties minimize leakage, withstand temperature variations up to 220C, and tolerate high pressures up to 150 bar.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Gaskets Category

Industrial Gaskets

Minimum Order Quantity : 1000 Pieces

Hardness : 4060 Shore A

Material : Other, Graphite with Stainless Steel

Outer Ring : Available

Medium : Other, Oils, Gases, Steam, Chemicals

Shape : Other, Round

Transformers Seals and Gaskets

Minimum Order Quantity : 500 Pairs

Hardness : 3090 Shore A

Material : Other, Nitrile Rubber, Cork, EPDM, Neoprene, Silicone

Outer Ring : Elastomeric, Metalclad

Medium : Other, Mineral Oil, Synthetic Oil, Transformer Oil

Shape : Other, Rectangular, Circular, Custom

Speedometer Gaskets

Minimum Order Quantity : 1000 Pairs

Hardness : 70 Shore A

Material : Other, Rubber composite

Outer Ring : Rubber Seal

Medium : Other, Hydrocarbon and Oil Resistant

Shape : Other, Circular

Quality Rubber washers

Minimum Order Quantity : 1000 Pieces

Hardness : 60 Shore A

Material : Other, HighGrade Rubber

Outer Ring : Precision Cut

Medium : Other, Water, Oil, Air

Shape : Other, Round

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS