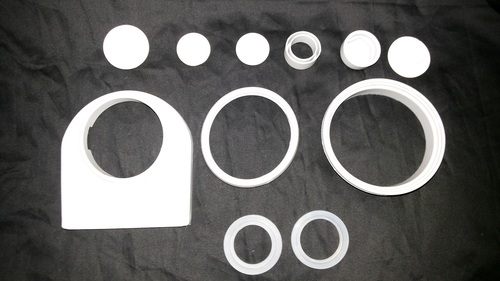

Enviromental Chambers Port Holes

Enviromental Chambers Port Holes Specification

- Tensile Strength

- High, suitable for maintaining chamber seals and pressure

- Tolerance

- 0.5 mm

- Components

- Port hole body, sealing gasket, mounting flange

- Rubber Type

- Silicone or Natural Rubber

- Flame Resistance Level

- Meets general laboratory safety standards

- Size

- Standard sizes available are 50 mm, 80 mm, and 100 mm diameter port holes

- Usage & Applications

- Designed for use in environmental chambers to enable flexible access and probe insertion while maintaining chamber integrity

- Part Type

- Port Hole Assembly

- Feature

- Leak-proof, easy to install, precise sealing, allows probe entry without loss of chamber conditions

- Resistance level

- Resistant to chemical, thermal, and mechanical stresses

- Natural Rubber

- Available as gasket material option

- Surface Finish

- Brushed stainless steel (body), Smooth finish (rubber gasket)

- Density

- 7.8 Gram per cubic centimeter(g/cm3)

- Temperature Resistance

- -40C to +150C

- Weight

- Varies per size, for 80 mm port approx. 700 g

- Width

- Customizable, typically ranges from 100 mm to 300 mm depending on chamber design

- Product Type

- Environmental Chamber Port Hole

- Diameter

- Typically 50 mm, 80 mm, or 100 mm

- Color

- Silver (for stainless steel body), Black/Grey (for rubber seal)

- Thickness

- 5 mm to 25 mm (varies by chamber panel and gasket design)

- Length

- As per chamber wall thickness, generally 50 mm to 200 mm

- Compression Ratio

- Optimized for gasket sealing, typically 20%

- Water Absorption

- Negligible for stainless steel and rubber components

- Hardness

- Shore A 60-70 (rubber gasket options)

- Thermal Conductivity

- Low (for gasket), High (for stainless steel)

- Style

- Round, integrated flange

- Material

- Stainless steel (body), Silicone/Natural Rubber (seal/gasket)

- Corrosion Resistance

- Excellent due to stainless steel

- Installation Mode

- Bolt-on design for easy mounting

- Application Industries

- Pharmaceutical, Electronics, Food Testing Labs

- Environmental Compliance

- RoHS and REACH compliant materials

- Custom Port Diameter

- Available on request

- Ambient Compatibility

- Suitable for humid and dry environments

- Maintenance

- Easy to disassemble and clean

- Operating Pressure Range

- Up to 2 bar

- Sealing Mechanism

- O-ring gasket with compression fitting

- Replacement Parts

- Gasket rings and flanges available

Enviromental Chambers Port Holes Trade Information

- Minimum Order Quantity

- 500 Pairs

- Main Domestic Market

- South India, Karnataka

About Enviromental Chambers Port Holes

Enclosed areas called "environmental chambers port holes" are used to imitate different environmental factors including temperature, humidity, light, and pressure. Applications for these chambers include product testing, research and development, and quality control. Environmental chamber Port holes are small, circular openings in the chamber walls that allow access to the interior of the chamber without disturbing the environmental conditions inside. These ports are typically made of durable materials such as stainless steel or acrylic and are designed to withstand the rigours of repeated use.

Superior Sealing and Integrity

Engineered for high tensile strength and precise compression, the O-ring gasket with compression fitting ensures reliable sealing even under demanding environmental chamber conditions. The leak-proof design supports probe and instrumentation access without any loss of chamber pressure, humidity, or temperature control.

Robust Materials and Versatile Design

Manufactured from brushed stainless steel, these port holes resist corrosion, chemical attack, and mechanical stress. The integrated flange and bolt-on assembly make installation straightforward in both humid and dry environments, with easy customization to suit chamber wall thicknesses and special diameters.

Easy Maintenance and Compliance

Each port hole assembly is designed for quick disassembly and hassle-free cleaning. Replacement gasket rings and flanges are readily available. The use of RoHS and REACH compliant, flame-resistant materials ensures suitability for sensitive industrial and laboratory applications.

FAQs of Enviromental Chambers Port Holes:

Q: How are the Environmental Chamber Port Holes installed?

A: The port holes feature a bolt-on design with an integrated flange, enabling straightforward and secure installation onto chamber walls of varying thickness. All necessary mounting hardware is provided, allowing for quick setup without the need for specialized tools.Q: What range of port diameters and thicknesses are available?

A: Standard port diameters are 50 mm, 80 mm, and 100 mm. Custom diameters can be manufactured upon request. The assembly accommodates wall thicknesses from 5 mm to 25 mm, and the length can be tailored to fit your chambers specific requirements.Q: When is it necessary to replace gasket rings or flanges?

A: Inspect gaskets and flanges during routine chamber maintenance. Replace the gasket ring if signs of wear, compression set, or damage appear, or if sealing integrity is compromised. Replacement parts are available as needed from the manufacturer or supplier.Q: Where can these port holes be used?

A: These port holes are ideal for environmental chambers in pharmaceutical R&D, electronics testing, and food analysis laboratories. Their construction and compatibility with both humid and dry environments make them suitable for a wide range of controlled chamber applications.Q: What are the main benefits of the O-ring gasket with compression fitting?

A: The optimized compression ratio of 20% ensures excellent leak resistance and chamber integrity under up to 2 bar pressure, while allowing probes and instruments to pass through without losing critical environmental conditions.Q: How easy is it to maintain or clean the port hole assembly?

A: The design allows easy disassembly by removing the bolts. Gaskets and flanges can be quickly replaced or cleaned, ensuring minimal downtime and operational continuity.Q: What environmental standards and compliance criteria do these assemblies meet?

A: All materials used in the port hole assemblies are RoHS and REACH compliant, and the flame resistance meets standard laboratory safety requirements, making them suitable for regulated industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Components Category

Rubber moulded components

Minimum Order Quantity : 1000 Pieces

Temperature Resistance : 40C to +220C (depends on rubber type)

Density : 1.1 Gram per cubic centimeter(g/cm3)

Surface Finish : Smooth, custom textured, or grained as needed

Natural Rubber : Available as an option

Resistance level : Good chemical, oil, abrasion and aging resistance

Silicon Medical Components

Minimum Order Quantity : 1000 Pairs

Temperature Resistance : 60C to +230C

Density : 1.25 Gram per cubic centimeter(g/cm3)

Surface Finish : Smooth/Glossy

Natural Rubber : No

Resistance level : High chemical and thermal resistance

Rubber Tubes

Minimum Order Quantity : 500 Pieces

Temperature Resistance : 40C to 120C

Density : 1.5 Gram per cubic centimeter(g/cm3)

Surface Finish : Matte

Natural Rubber : Included

Resistance level : High resistance to wear and tear

Rubber gasketss

Temperature Resistance : 30C to +120C

Density : 1.7 Gram per cubic centimeter(g/cm3)

Surface Finish : Smooth

Natural Rubber : Yes

Resistance level : High resistance to abrasion and compression

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS