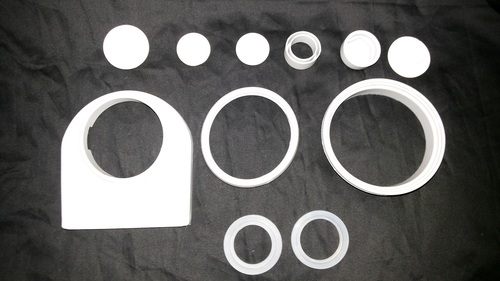

Flexible Rubber Caps

Flexible Rubber Caps Specification

- Part Type

- Protective Cap/Cover

- Components

- Single-piece molded cap

- Flame Resistance Level

- Standard, not flame retardant unless specified

- Density

- 1.6 Gram per cubic centimeter(g/cm3)

- Width

- Varies (customizable as per requirement)

- Nitrogen Content (%)

- Negligible

- Diameter

- 12 mm, 16 mm, 20 mm, up to 50 mm (custom available)

- Volatile Matter (%)

- <2%

- Resistance level

- Excellent against chemicals and abrasion

- Material

- EPDM/Neoprene/Nitrile Rubber

- Tensile Strength

- 10 MPa

- Water Absorption

- Low

- Temperature Resistance

- -30C to +120C

- Product Type

- Flexible Rubber Cap

- Tolerance

- 0.2 mm

- Compression Ratio

- High flexibility, up to 30% compression

- Rubber Type

- Synthetic Rubber (EPDM/Neoprene)

- Thickness

- 1 mm to 3 mm

- Length

- 25 mm to 100 mm (custom available)

- Natural Rubber

- No, made from synthetic rubber compound

- Style

- Push-on

- Hardness

- Shore A 55-70

- Color

- Black

- Surface Finish

- Smooth, matt

- Size

- Available in multiple sizes to suit different diameters

- Weight

- Lightweight, varies based on size

- Ash %

- <1%

- Feature

- Flexible, reusable, anti-slip, chemical resistant

- Thermal Conductivity

- Very low, offers insulation

- Usage & Applications

- Primarily used for capping pipe ends, protecting threads, masking during coating or painting, and safeguarding sensitive parts.

- OEM Customization

- Available as per specification

- Ozone Resistance

- Excellent, resists cracking or degradation

- Manufacturing Process

- Injection molding

- Installation Method

- Manual push-fit application

- Environmental Compliance

- RoHS compliant

- UV Resistance

- Good (suitable for outdoor use)

- Elongation at Break

- 250%

- Fitting Shape

- Round

- Electrical Insulation

- Provides basic insulation properties

- Storage Conditions

- Store in cool and dry environment, away from direct sunlight

- Odor

- Low odor, non-offensive

About Flexible Rubber Caps

Flexible Rubber Caps: Robust Features & Competitive Edge

Our Flexible Rubber Caps stand out with exceptional ozone resistance, superb elongation at break (250%), and seamless anti-slip performance. Engineered using advanced injection molding, their smooth finish and tolerance of 0.2 mm guarantee a snug, reliable push-fit. Their low odor, low ash, and negligible nitrogen content ensure a cleaner, more user-friendly experience. The caps are highly flexible and reusable, supporting high compression ratios and delivering noteworthy chemical and abrasion resistance. Choose these rubber caps for outstanding cost-effectiveness and flexibility.

Packaging, Sample, and Supply Information for Flexible Rubber Caps

We offer tailored packaging based on the proposal amount to suit your shipment needs, ensuring products are shipped securely and efficiently at the lowest price. Our supply ability accommodates bulk orders, with consistent availability for manufacturers, exporters, and suppliers across India and globally. Samples are available on request, and our sample policy is designed for easy evaluation before bulk purchase. Trust us to deliver a seamless purchasing experience for every client.

FAQs of Flexible Rubber Caps:

Q: How are the flexible rubber caps installed?

A: The flexible rubber caps are installed using a manual push-fit application; simply align and press the cap over the intended surface for a snug, secure fit.Q: What materials are available for these rubber caps?

A: Our rubber caps are manufactured from high-grade synthetic rubber compounds, including EPDM, Neoprene, and Nitrile, offering notable resistance to chemicals, abrasion, ozone, and UV exposure.Q: When is it best to use these rubber caps?

A: These caps are best used for protecting pipe ends, masking during coating or painting, safeguarding threaded parts, and covering sensitive components, especially in environments requiring strong UV and ozone resistance.Q: Where can the rubber caps be utilized?

A: They can be utilized in various industries, including manufacturing, automotive, electrical, and constructionessentially wherever robust protection and basic insulation are needed for pipes, rods, or exposed threads.Q: What benefits do these caps provide compared to alternatives?

A: These rubber caps offer a blend of affordability and high performance, with excellent flexibility, resistance to environmental factors, and customizable options, making them a noteworthy solution over less adaptable or lower-resistance products.Q: What is the process for OEM customization?

A: OEM customization is available according to your exact specifications; simply provide the required measurements and material preferences, and the caps will be manufactured via injection molding to meet your needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Components Category

Rubber moulded components

Minimum Order Quantity : 1000 Pieces

Material : Natural rubber, EPDM, Nitrile, SBR, Silicone, Neoprene, or as specified

Components : Seals, gaskets, bushings, bellows, washers, couplings, boots, Orings, buffers

Part Type : Moulded mechanical part

Style : Customized as per requirement

Surface Finish : Smooth, custom textured, or grained as needed

Silicon Transparent tube

Minimum Order Quantity : 500 Meters

Material : Premium grade Silicon Rubber

Components : Single extruded silicon tube

Part Type : Tubing

Style : Flexible Tubing

Surface Finish : Smooth, Glossy

Rubber seals23

Material : Synthetic Rubber (EPDM/NBR/Silicone)

Components : Single or multiple compound grades

Part Type : Industrial Seal

Style : Extruded & Molded

Surface Finish : Smooth/Matte

Rubber Gromet

Minimum Order Quantity : 1000 nos

Material : Natural rubber / Synthetic rubber (EPDM/NBR/Silicone)

Components : Single rubber compound

Part Type : Protective Insert/Seal

Style : Round, Split, Blind

Surface Finish : Smooth / Matte

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS