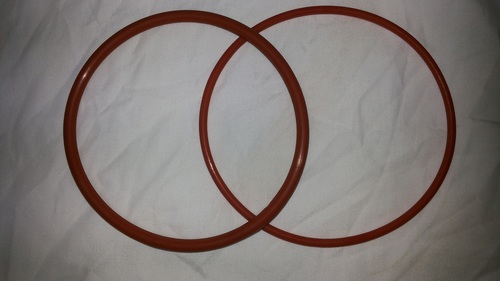

Heavy Rubber O Rings

Heavy Rubber O Rings Specification

- Resistance level

- Excellent

- Nitrogen Content (%)

- 0.5%

- Volatile Matter (%)

- 1.5%

- Tolerance

- 0.1 mm

- Size

- Varied Sizes Available (Standard and Custom)

- Flame Resistance Level

- Standard - Optional on Request

- Temperature Resistance

- -40C to +120C

- Ash %

- 1%

- Feature

- High Durability, Oil & Chemical Resistant, Weatherproof

- Material

- Heavy Duty Rubber (Nitrile, EPDM, Neoprene Optional)

- Length

- As Required

- Water Absorption

- Low

- Hardness

- 705 Shore A

- Product Type

- Heavy Rubber O Ring

- Weight

- Varies with Size

- Thermal Conductivity

- Low

- Tensile Strength

- 15-20 MPa

- Part Type

- Sealing Ring/O Ring

- Thickness

- Up to 50 mm

- Surface Finish

- Smooth

- Components

- Elastomer Only

- Color

- Black

- Natural Rubber

- Available on Request

- Style

- Round Cross Section

- Density

- 1.2 Gram per cubic centimeter(g/cm3)

- Rubber Type

- Heavy Duty Industrial Rubber

- Usage & Applications

- Industrial Sealing, Hydraulic and Pneumatic Machinery, Heavy Duty Equipment

- Compression Ratio

- 15-30%

- Diameter

- Up to 500 mm or Customized

- Width

- Customizable

- Abrasion Resistance

- High

- Ozone Resistance

- Yes

- Reinforcement

- None (Solid Rubber)

- Minimum Order Quantity

- As per Requirement

- Packaging

- Standard Box or Customized

- Corrosion Resistance

- Yes

- Elongation at Break

- 200%-300%

- Oil Resistance

- Supports Contact with Mineral Oils

- Durometer Range

- 60-80 Shore A

- UV Resistance

- Yes

- Installation

- Press-fit/Grooved Applications

- Shape

- Circular O-Ring

- Electrical Properties

- Non-Conductive

Heavy Rubber O Rings Trade Information

- Minimum Order Quantity

- 1000 nos Pieces

- Main Domestic Market

- South India, Karnataka

About Heavy Rubber O Rings

Heavy rubber O-rings are a type of O-ring that is designed to withstand high pressure and extreme temperatures. They are typically made from synthetic rubber materials, such as Viton or EPDM, which have excellent chemical and heat resistance properties.Heavy rubber O-rings are used in a wide range of industrial applications, including in hydraulic systems, chemical processing equipment, and aerospace applications. They are capable of sealing against fluids such as water, oil, and fuel, as well as gases like air and nitrogen.The main advantage of heavy rubber O-rings is their ability to withstand extreme conditions without deteriorating. They can withstand high temperatures up to 400 degrees Fahrenheit and can resist exposure to a variety of chemicals, including acids, bases, and solvents. This makes them ideal for use in harsh environments where other materials may fail.When selecting heavy rubber O-rings, it is important to consider the specific requirements of the application. Factors such as temperature, pressure, chemical compatibility, and size will all play a role in determining the best type of O-ring to use. Proper installation and maintenance are also crucial to ensure that the O-rings function correctly and prevent costly leaks and downtime.Engineered for Demanding Environments

Heavy Rubber O Rings are designed to withstand extreme working conditions. Their high abrasion, UV, ozone, and oil resistance make them suitable for use in heavy duty equipment, industrial sealing, and machinery exposed to harsh elements. The material optionsNitrile, EPDM, or Neopreneensure the right resistance level for a variety of applications.

Customizable for Versatile Applications

These circular O-rings come in a vast range of sizes, diameters, and thicknesses to fit multiple press-fit and grooved installation requirements. Whether you need large diameters up to 500 mm or specific thicknesses, tailored solutions are available to meet your project requirements. Both standard box and custom packaging ensure safe and convenient delivery.

Excellent Mechanical & Protective Properties

Each O-ring offers robust tensile strength (15-20 MPa), 200%-300% elongation at break, low water absorption, non-conductive electrical properties, chemical and oil resistance, and strong weatherproofing. Precision manufacturing with a smooth surface finish and 0.1 mm tolerance guarantees reliable, leak-free performance in industrial settings.

FAQs of Heavy Rubber O Rings:

Q: How are heavy rubber O rings installed in industrial machinery?

A: These O-rings are designed for press-fit or grooved installations. Simply place the ring into the designated groove or channel on the machinery component, ensuring that it fits snugly to create an effective seal. Proper installation prevents leaks and maintains pressure integrity in equipment.Q: What makes these O-rings highly suitable for heavy duty industrial applications?

A: Their construction from high-performance rubbers like Nitrile, EPDM, or Neoprene gives them excellent resistance to abrasion, oils, chemicals, UV light, and ozone. A tensile strength of 15-20 MPa and elongation at break of 200%-300% ensure these O-rings endure demanding operating conditions without losing shape or effectiveness.Q: When should I choose a customized size or thickness for my application?

A: Opt for a custom size or thickness when standard dimensions do not fit your sealing groove or machinery specifications. Customization ensures a perfect match, optimal sealing, and longevity in specialized equipment or unique operating environments.Q: Where can these heavy rubber O rings be used effectively?

A: They are ideal for hydraulic and pneumatic machinery, industrial sealing in heavy duty equipment, and environments requiring resistance to abrasion, chemicals, oil, and varying weather conditions. Common sectors include manufacturing, construction, and fluid power applications.Q: What is the process for ordering and packaging these O-rings?

A: You can place orders based on your quantity and customization requirements. Packaging is available in standard boxes or can be tailored as per your needs to ensure product safety during transport. Minimum order quantity is flexible and as per client specifications.Q: How do these O-rings benefit industrial operations?

A: They provide superior sealing against fluid and gas leaks, resist degradation from oils and chemicals, withstand extreme temperatures (from -40C to +120C), and deliver enduring performance in harsh environmentsminimizing downtime and maintenance for machinery.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber O rings Category

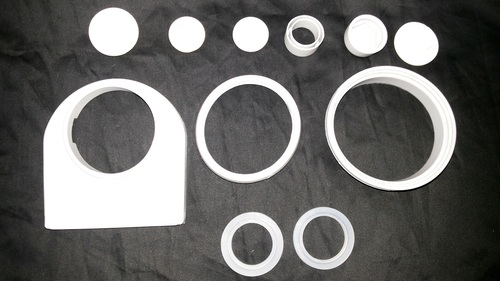

Rubber Caps and Rings

Minimum Order Quantity : 1000 Pieces

Rubber Type : EPDM, Silicone, NBR

Density : 1.25 Gram per cubic centimeter(g/cm3)

Style : Solid, Flexible, Round

Width : Variable (customizable based on ring or cap type)

Usage & Applications : Ideal for sealing, masking, protection of threads and pipes, electrical insulation, and covering exposed parts in automotive, industrial, and electronic equipment

Rubber O rings

Minimum Order Quantity : 1000 Pieces

Rubber Type : NBR, EPDM, Silicone, Viton

Density : 1.5 Gram per cubic centimeter(g/cm3)

Style : Round crosssection

Width : Varies (customizable, commonly 1 mm to 10 mm)

Usage & Applications : Sealing in hydraulic, pneumatic systems, automotive, plumbing, and industrial machinery

Industrial Rubber O rings

Minimum Order Quantity : 1000 Pieces

Rubber Type : Natural and Synthetic (EPDM/NBR/Silicone/Viton)

Density : 1.8 Gram per cubic centimeter(g/cm3)

Style : Round

Width : Standard widths available, customizable as per requirement

Usage & Applications : Sealing applications in industrial machinery, hydraulic systems, plumbing, and automotive industries

Silicon O Rings

Minimum Order Quantity : 1000 Pairs

Rubber Type : Silicone

Density : 1.1 Gram per cubic centimeter(g/cm3)

Style : Standard round crosssection

Width : Customizable, generally ranges from 2 mm to 10 mm

Usage & Applications : Sealing, gasketing, preventing leakages in plumbing, automotive, industrial, and laboratory environments

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS