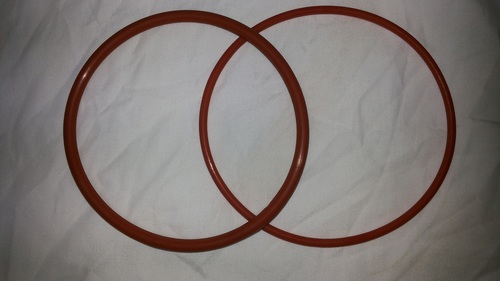

Silicon O Rings

Silicon O Rings Specification

- Compression Ratio

- Recommended 25% - 35%

- Diameter

- Varies as per model, 5 mm to 200 mm

- Natural Rubber

- No, made from synthetic silicone rubber

- Weight

- Lightweight, depends on size

- Length

- Continuous/As per size

- Feature

- High elasticity, non-reactive, inert, odorless

- Size

- Various sizes available from 5 mm to 200 mm outer diameter

- Tolerance

- 0.05 mm

- Components

- Single molded silicone ring

- Density

- 1.1 Gram per cubic centimeter(g/cm3)

- Flame Resistance Level

- Self-extinguishing in some grades

- Tensile Strength

- 9 MPa

- Thermal Conductivity

- 0.2 W/mK

- Thickness

- 1 mm to 10 mm

- Surface Finish

- Smooth

- Material

- Silicone rubber

- Water Absorption

- Low, <1%

- Product Type

- O Ring

- Part Type

- O-ring gasket

- Resistance level

- High resistance to chemicals and temperature extremes

- Hardness

- 60 5 Shore A

- Temperature Resistance

- -60C to +230C

- Color

- Red, translucent, clear

- Ash %

- Less than 1%

- Rubber Type

- Silicone

- Usage & Applications

- Sealing, gasketing, preventing leakages in plumbing, automotive, industrial, and laboratory environments

- Width

- Customizable, generally ranges from 2 mm to 10 mm

- Style

- Standard round cross-section

- Package Type

- Polybag, carton box

- Electrical Insulation

- Good dielectric properties

- Reusability

- Reusable, long service life

- UV & Ozone Resistance

- Excellent

- Chemical Resistance

- Excellent resistance to acids, alkalis, and solvents

- Standard Compliances

- FDA, RoHS approved grades available

- Manufacturing Process

- Molded or extruded

- Compression Set

- 25% (22 hours at 175C)

- Operating Pressure Range

- Up to 10 bar (depends on application)

- Elongation at Break

- 350%

Silicon O Rings Trade Information

- Minimum Order Quantity

- 1000 Pairs

- Main Domestic Market

- South India, Karnataka

About Silicon O Rings

We have brought Silicone O rings, which are employed in the production of pharma equipment, automobile designs, and food production units. They are special products which are specifically known for their exceptional strength, flexibility, and resistance to dangerous chemicals, and extreme temperatures. Thereby, leading to increase their demands in the market. The offered Silicone O rings offer several benefits such as they can be ideal options in high-temperature situations. This is as a result of their noteworthy tolerance to extreme temperatures. They also showcase high resilience against chemicals and UV radiation makes them ideal for usage in outdoor conditions.

Exceptional Chemical and Temperature Resistance

Silicon O Rings provide advanced resistance to acids, alkalis, solvents, and extreme temperatures. Their robust material ensures reliable performance in both harsh environmental and operational conditions, making them a preferred choice for critical sealing applications. They are inert, non-reactive, and maintain elasticity over extended use.

Versatile Sizing and Customization

These O-rings are available in sizes ranging from 5 mm to 200 mm outer diameter and widths typically between 2 mm and 10 mm. Custom dimensions can be manufactured to suit unique project requirements, offering flexibility for specific applications in various industries.

Compliance and Safe Use

Silicon O Rings meet FDA and RoHS standards, ensuring safe and approved use in food, pharmaceutical, and environmentally conscious environments. Selected grades offer self-extinguishing properties and low water absorption, further enhancing their suitability for demanding applications.

FAQs of Silicon O Rings:

Q: How do Silicon O Rings withstand extreme temperatures and harsh chemicals?

A: Silicon O Rings are made from synthetic silicone rubber that offers excellent resistance to acids, alkalis, solvents, and severe temperature extremes, maintaining performance between -60C and +230C.Q: What is the recommended compression ratio for installing these O-rings?

A: A compression ratio of 25% to 35% is recommended to ensure effective sealing without compromising the rings durability or elasticity during installation.Q: When should Silicon O Rings be chosen over natural rubber O-rings?

A: Silicon O Rings should be used when high chemical resistance, wide operating temperature range, and superior elasticity are required, making them more suitable for industrial, automotive, and laboratory applications than natural rubber options.Q: Where can these O-rings be applied effectively?

A: They are ideal for use in plumbing systems, automotive engines, industrial machinery, and laboratory equipment, wherever effective sealing and leak prevention are crucial.Q: What is the manufacturing process for these O-rings?

A: Silicon O Rings are produced through either molding or extrusion processes, ensuring consistent quality and customizable size options to fit varied requirements.Q: How does the long service life of these O-rings benefit users?

A: Due to high chemical resistance, low compression set, and reliable elasticity, Silicon O Rings offer reusability and extended service life, reducing maintenance frequency and replacement costs for users.Q: What packaging options are available for these O-rings?

A: Depending on order quantity and customer preference, O-rings are packaged in durable polybags or secure carton boxes to ensure safe transit and storage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber O rings Category

Rubber Caps and Rings

Minimum Order Quantity : 1000 Pieces

Density : 1.25 Gram per cubic centimeter(g/cm3)

Flame Resistance Level : Optional flameretardant grades

Feature : High durability, weather resistant, and flexible

Length : Customizable, standard lengths from 10 mm to 100 mm

Components : Single piece rubber construction

Heavy Rubber O Rings

Minimum Order Quantity : 1000 nos Pieces

Density : 1.2 Gram per cubic centimeter(g/cm3)

Flame Resistance Level : Standard Optional on Request

Feature : High Durability, Oil & Chemical Resistant, Weatherproof

Length : As Required

Components : Elastomer Only

Industrial Rubber O rings

Minimum Order Quantity : 1000 Pieces

Density : 1.8 Gram per cubic centimeter(g/cm3)

Flame Resistance Level : Vary by material; available in flameretardant variants

Feature : Durable, Flexible, Leakproof, Weather Resistant

Length : Continuous or as per required size

Components : Single component molded ring

Rubber O rings

Minimum Order Quantity : 1000 Pieces

Density : 1.5 Gram per cubic centimeter(g/cm3)

Flame Resistance Level : Basic (custom compounds available on request)

Feature : Oil resistant, waterproof, high elasticity, antiabrasive

Length : Continuous or cuttolength as per requirement

Components : Singlepiece Oring

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS