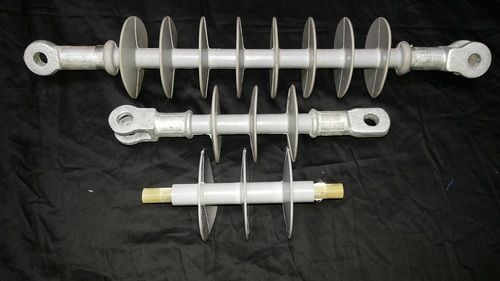

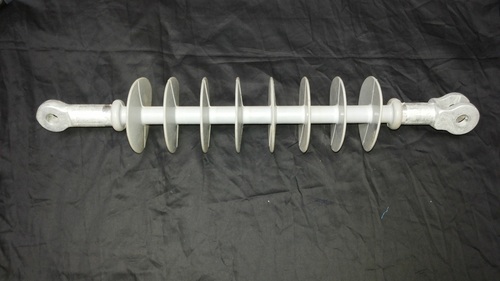

High Voltage Insulators

High Voltage Insulators Specification

- Tolerance

- 2 mm

- Part Type

- Insulation Component

- Resistance level

- Withstands voltage ratings up to 36 kV or higher

- Size

- Standard sizes available; customizable as per requirement

- Style

- Disc/Pin/Post type

- Thermal Conductivity

- Low

- Material

- Porcelain / Composite Polymer

- Weight

- Approx. 3-6 kg (depending on type)

- Product Type

- High Voltage Insulator

- Surface Finish

- Glazed, smooth

- Feature

- High insulation, weather resistance, anti-tracking

- Color

- Brown / Grey

- Components

- Core, shed, end fittings, metal caps

- Hardness

- 7 Mohs (Porcelain)

- Water Absorption

- <0.5% (Porcelain)

- Diameter

- 178-280 mm

- Usage & Applications

- High voltage electrical transmission and distribution systems, substations, and industrial electrical networks

- Flame Resistance Level

- Self-extinguishing (Polymer type)

- Temperature Resistance

- -40C to +150C

- Width

- Variable as per model specification

- Thickness

- Variable, depending on design

- Length

- Maximum length up to 420 mm, model dependent

- Density

- 2.5 Gram per cubic centimeter(g/cm3)

- Tensile Strength

- High mechanical strength, typically >40 MPa

- Hydrophobicity

- Superior (polymer insulators)

- Mechanical Load Strength

- Up to 10 kN (Disc type)

- Compliance Standards

- IEC 60168, IEC 60383, ANSI C29

- UV Resistance

- Excellent, suitable for outdoor use

- Electrical Insulation Strength

- Up to 125 kV BIL (Basic Insulation Level)

- End Fitting Material

- Galvanized steel / forged steel

- Creepage Distance

- 295550 mm

- Service Life

- >30 years

- Mounting Type

- Cap and pin, or post

High Voltage Insulators Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Main Domestic Market

- South India, Karnataka

About High Voltage Insulators

High Voltage Insulators we offer are of advanced mechanical strength and can endure the wind load and conductor load. These are of high electrical resistance and can reduce the leakage currents. The insulators make use of insulating material so that the attained dielectric strength is high. Supplied insulators have been made to protect against electrical hazards, such as arcing, electrical discharge etc. Supplied insulators are made to fight against the electrical accidents and failures. The insulators are made for ensuring the safety of equipment and workers.

Exceptional Electrical and Mechanical Strength

Designed for high voltage applications, our insulators provide outstanding insulationup to 125 kV BILand withstand substantial mechanical loads up to 10 kN (disc type). The materials and construction ensure minimal water absorption, high tensile strength, and long-lasting stability even in challenging operating conditions.

Advanced Outdoor Performance and Durability

These insulators offer excellent UV resistance and retain hydrophobicity for polymer models, ensuring weather resistance and anti-tracking properties. With a glazed smooth finish, low thermal conductivity, and self-extinguishing flame resistance (polymer), these components are tailored for outdoor transmission and distribution use.

Certified Quality for Extended Service Life

Manufactured to exacting IEC and ANSI standards, each insulator guarantees over three decades of reliable service. The flexibility in size, thickness, and end fitting materialsgalvanized or forged steelallows customization for varying electrical network requirements in substations and industrial systems.

FAQs of High Voltage Insulators:

Q: How do high voltage insulators with 295550 mm creepage distance improve electrical safety?

A: These insulators enhance electrical safety by providing an extended creepage distance, which reduces the risk of flashover and leakage currents under high voltage conditions. This is critical for preventing insulation failures in outdoor and polluted environments.Q: What are the key benefits of using polymer over porcelain insulators for outdoor applications?

A: Polymer insulators offer superior hydrophobicity, excellent UV resistance, and lighter weight compared to porcelain. They also exhibit self-extinguishing flame resistance and maintain high performance in polluted and wet conditions, making them ideal for outdoor installations.Q: When should I choose a disc, pin, or post type insulator?

A: The choice depends on your application: disc type is preferred for long transmission lines requiring high mechanical strength, pin type for distribution lines at lower voltages, and post type for substations or settings needing rigid mounting and specific mechanical configurations.Q: Where are these high voltage insulators typically used?

A: These insulators are widely used in high voltage electrical transmission and distribution networks, substations, and industrial electrical systems to ensure safe, reliable insulation, and mechanical support for conductors.Q: What is the standard process for customizing insulator size or specifications?

A: To customize an insulator, provide your voltage, mechanical load, and dimensional requirements. Our team will design the insulator according to IEC/ANSI standards, ensuring the creepage distance, size, and end fittings meet your systems specifications.Q: How does the surface finish and water absorption rate affect performance?

A: A glazed, smooth finish helps prevent surface tracking and contaminant buildup, while a low water absorption rate (<0.5% for porcelain) ensures that dielectric strength is maintained in humid or wet conditions, extending the insulators operational life.Q: What compliance standards assure the reliability of these insulators?

A: Our insulators comply with IEC 60168, IEC 60383, and ANSI C29 standards, which govern electrical, mechanical, and environmental performanceensuring predictable durability, safety, and global application suitability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Insulators Category

Industrial Rubber Pads

Minimum Order Quantity : 1000 Pieces

Product Type : Industrial Rubber Pad

Weight : Depends on size/thickness

Material : Rubber (NR, SBR, or blend)

Surface Finish : Smooth or textured

Feature : Heavy Duty, Nonslip, Shock Absorption, Durable

Voltage Insulators

Minimum Order Quantity : 1000 Pieces

Product Type : Voltage Insulator

Weight : 1 10 kg depending on design

Material : Porcelain / Polymer / Composite

Surface Finish : Glazed / Smooth

Feature : High dielectric strength, weather and UV resistant

Rubber insulation

Minimum Order Quantity : 500 Pieces

Product Type : Rubber insulation

Weight : Lightweight

Material : Rubber

Surface Finish : Smooth

Feature : Durable and insulating material

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS